Description

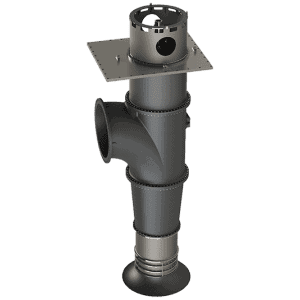

Our Canned Motor Retrofits replace your existing mechanical seal and air-cooled motor. It couples directly to your existing pump case, allowing you to keep your existing pump and eliminate the problematic mechanical seal.

Key Benefits:

- Keep your existing pump installation

- No mechanical seal means no leakage

- Inherently safe

- Double layer pressure boundary containment

- Self-lubricated bearings – no external lubrication system needed

- Eliminates pump and motor alignment – common shaft

- Thrust bearing provides reliability during upset pump conditions

- Low noise

Applications

Hayward Tyler Canned Motor Pump Retrofits are ideal for the following typical plant applications:

NUCLEAR

- Reactor Water Clean-Up (RWCU)

- Fuel pool

- Heavy water transfer/collection

- Main coolant pump

- Blow Down System Drain/Recirculation

- Emergency diesel fuel transfer

- Radwaste

- Spent fuel pool aux cooling system

- Reactor coolant drain

CHEMICAL / PETROCHEMICAL

- Acids

- Ammonia

- Benzene

- Butenol

- Caustic

- Crude Ester

- Formaldehyde

- Heat transfer oils (Dowtherm, Therminol, Texatherm, etc.)

- Hydrogen Sulfide

- Nickel Catalyst

- Nitroparafins

- Olefins

- Reactor circulation/injection

- Titanium tetrachloride

Ideal for fluids with the following properties:

- High volatility

- Carcinogenic

- Corrosive

- Lethal

- High temperature

- Low temperature

- Radioactive

- Polymerizing