Description

Spiro-Gills Products Ltd is the UK’s premier manufacturer of Finned Tubes for air-cooled heat exchangers. Because good quality cooling water is either too costly or unavailable, such exchangers are relied upon heavily by most process and power generation plants throughout the world.

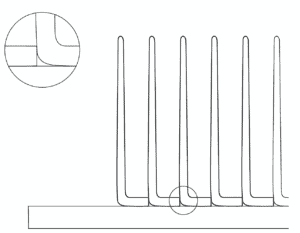

The heart of the air-cooled heat exchanger is the extended surface – the section where heat is transferred.

This surface is composed of helical high-finned tubes which need to be replaced from time to time due to corrosion, fouling or damage – either to the fins or to the base material.

We supply applied fin tube in using four methods. Their differences are detailed further down the page. We can supply replacement finned tubes to suit your planned shutdowns or for emergency use.

Our McElroy finning machines are recognised as the most efficient and reliable for the manufacture of applied finned tubes.

Type of Finned Tube

| Grooved Fin (Embedded Fin)

Application: High-efficiency fin for high operating temperatures Upper limiting temperature: 400°C Manufacture: A helical groove is formed in base tube displacing of material and fin is wound into the groove under tension, followed by backfilling of the displaced material to lock the fin root into the tube. Fin materials: Aluminium Base tube materials: |

| Wrapped Fin

SG-L Fin (Wrapped Fin) Application: Standard fin for low-temperature application where some degree of tube wall protection is required Upper limiting temperature: 120°C Manufacture: Fin foot is pre-formed into L shape and applied to base tube under tension. The adjacent fins abut one another, giving a degree Fin materials: Aluminium Base tube materials: Any metallic material |

| Overlapped L Fin

SG-LL Fin (Overlapped L Fin) Application: Standard fin for low-temperature applications giving increased atmospheric corrosion protection of the base tube. Upper limiting temperature: 180°C Manufacture: Fin foot is pre-formed into an LL shape (overlapped LL) and applied to base tube under tension. However, foot is pre-shaped to give overlap of one foot onto another, thereby improving base tube protection and thermal contact area Fin materials: Aluminium Base tube materials: Any metallic material |

| Knnurled L Fin

SG-K Fin (Knurled L Fin) Application: Standard fin for medium-temperature applications, giving increased atmospheric corrosion protection to the outer surface of the base tube Upper limiting temperature: 250°C Manufacture: Fin foot is pre-formed into an L shape and applied to base tube under tension. Knurling tools both precede and follow the laying down of the fin foot so that the fin material is locked into the pre-knurled tube. This gives up to 50% greater thermal contact area than standard L fin and also ensures an airtight fin to tube bond, resulting in greater tube protection Fin materials: Aluminium Base tube materials: Any metallic material |

TYPICAL APPLICATIONS

The wide range of uses for helical high-finned tubes includes:

- Steam condensers

- Oil coolers

- Air pre-heaters

- Product coolers – gas, chemicals, petrochemicals, oil etc

- Overhead condensers

- Water coolers